International Maritime Exhibition: Ship engines, transmissions & more

On many ships these days we see so-called four-stroke medium-speed engines. They typically run around 400-900 RPM.

BHPian Jeroen recently shared this with other enthusiasts.

In 1976, I started at the Dutch Merchant Naval Academy in Amsterdam, the Netherlands, as a student. Four years later, of which the 3rd year was spent aboard a Dutch General Cargo ship (full 365 days) I graduated. I spent the next 10 years as a Marine Engineer working for various shipping companies. Eventually made it to Chief Engineer. I have worked on a large number of different ships. From general cargo to bulk carriers, and container vessels. Most of my time at sea was spent on ocean-going tugs and anchor-handling vessels and a few other offshore support types of vessels.

Although my sailing days are long gone, I have always remained interested in the marine industry. Every year, for as long as I can remember, the Netherlands has held a huge international maritime congress, known as Europort. Europort is essentially the harbour area of Rotterdam. To date, Rotterdam is still among the largest and most modern harbours in the world. The Netherlands has a very long maritime tradition and there is a considerable maritime industry based in the Netherlands. Ranging from building superyachts, tub boats, maintenance ships propellers, electronics and lots more.

We have several threads on the forum about the (merchant) navy and we have several members who worked or are still working in this industry.

I visited Europort 2023 earlier this week and this thread is a collection of what I came across. Although a lot of it is maritime-related (Duh!) it also shows a very wide range of technology and its various applications. So I hope you enjoy it.

This event is not open to the general public. But it is not that difficult to get a free entrance ticket. I mean if they let me in, anybody can get in. So on Tuesday I drove my Mini to the nearby station and took the train and bus to the Ahoy Congress Halls in Rotterdam.

The images I will be showing are not sorted in any particular order or topic. It just shows how I wandered around this massive event, spread out over 8 halls.

TeamBHP being a car forum you will be happy to see, that the very first thing I came across was a car!! For the life of me, I can’t remember what it was doing here. One of the companies involved must have some relation with the maritime industry.

One of the first things I bumped into was the Volvo Diesel. You will see a lot more (Diesel) engines. I had a good look at this one as it was very similar to the little Volvo F16 Truck Engine I built not too long ago.

As you would imagine, there was a lot of emphasis on various environmental themes. There were several engines, running on alternate fuel, such as Hydrogen! These sorts of engines have already been in use for some years. Not just in the merchant navy, but also in stationary shore applications.

This particular engine is rated at 1000kW (1341HP) at 1000RPM.

Lots and lots of very interesting and very detailed ship models! I have taken several images of various kinds of ships. This is a small cargo ship with two modern sail arrangements. It enables fuel efficiency.

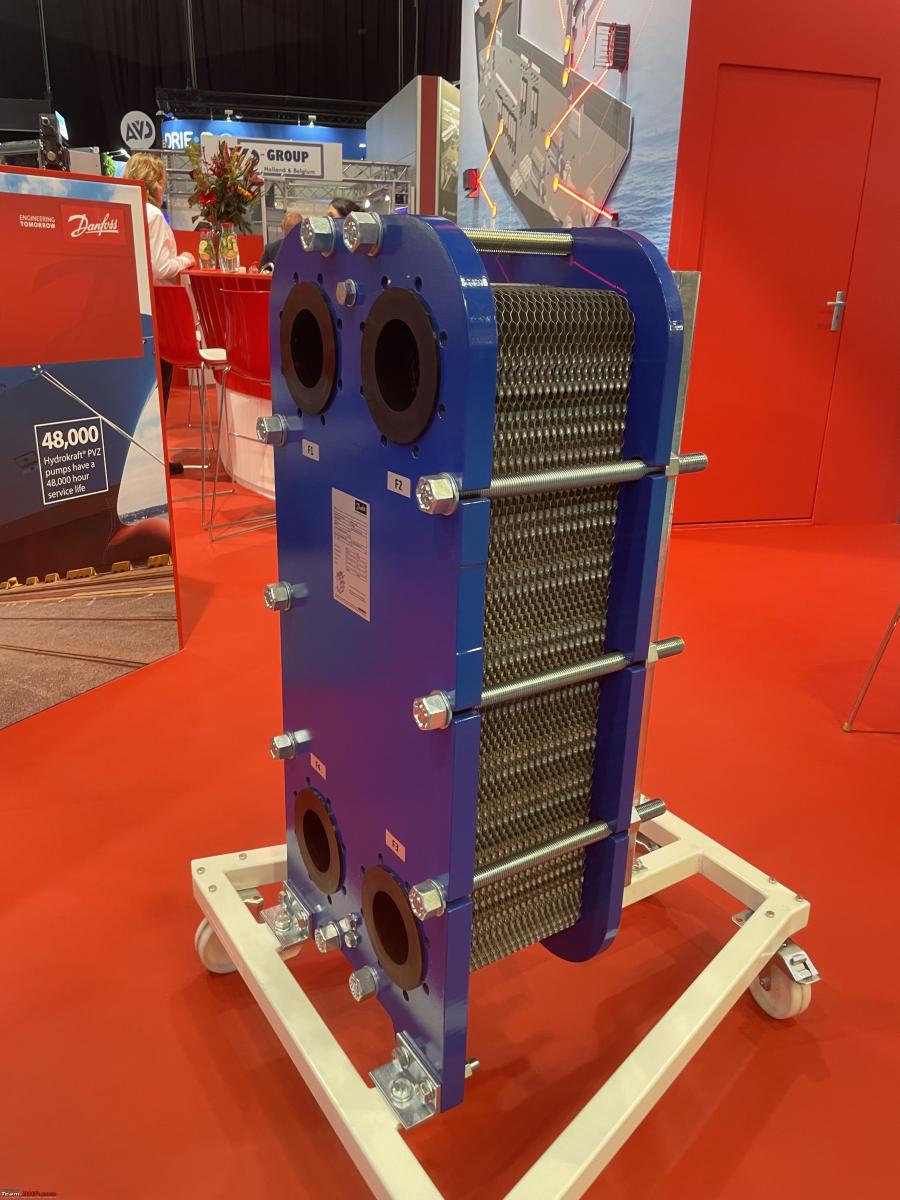

For all of you who wondered what a modern heat exchanger looks like, look no further. These so-called plate coolers have been in use for a very long time. I have worked on them. We used them to cool the engine cooling water (freshwater) with sea water (salt water). Especially if you operate in shallow waters or river estuaries you might end up with a lot of mud inside these things. They have to be taken apart and each plate has to be cleaned individually.

One of my favourite models I came across; was a very smart model of a powerful harbour tug. Look at the detailing on it!

Petrolheads will recognize the name of this company, ZF. They are also big in the maritime industry providing all kinds of very fancy and huge reduction gear. On merchant ships for best efficiency, the ship propellers can’t be turning too fast. On very very large two-stroke engines, the propellor is coupled directly, via a propellor shaft to the engine. It will run between say 40-180 RPM. On many ships these days we see so-called four-stroke medium-speed engines. They typically run around 400-900 RPM. This also means you need a reduction gear in between the engine and the propellor (shaft) to reduce the propellor RPM.

Here you see such a reduction gear (on the right), on the left, you see an e-motor that provides power as well. So this is a hybrid type of setup.

This looks pretty simple, but it is a phenomenal innovative design. This is a section of a propellor shaft, made entirely out of composite! I had never seen anything like it. I had no idea composites were suitable for these very high torques. They did tell me that these are designed for one particular direction of rotation. So it won’t work on reversible engines.

The main advantages compared to traditional steel prop shafts:

- Maintenance-free due to corrosion resistance

- Low mass moment of inertia

- Low damping factor

- Low weight

Especially the low weight is very important because less weight means better fuel efficiency!

Every ship will have hundreds if not thousands of valves. So there were a lot of valves on display as you can imagine. This is a so-called butterfly valve. Valves come in a huge variety of different designs and materials.

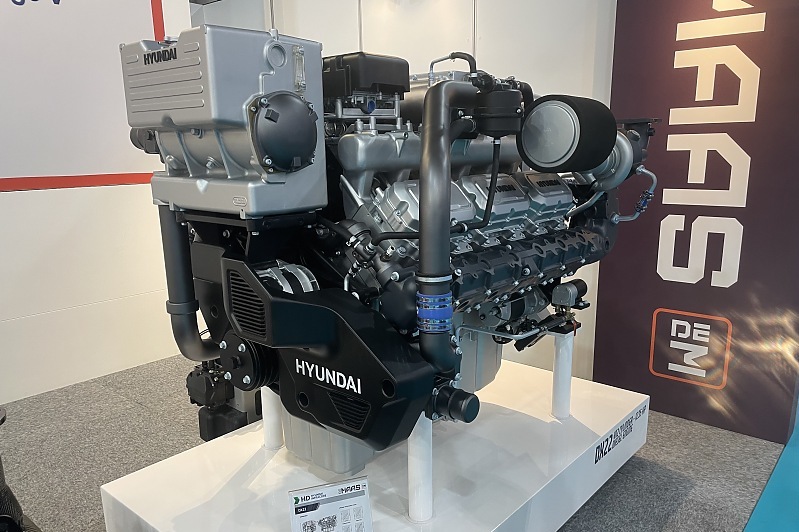

Another diesel engine, A Hyundai

This stand had some interesting things. This is all about tugs, their winch and various other machinery to keep cables and towing wires fixed in place. These days all operated from the bridge, hydraulically. In my days, we had to secure the towing ropes manually. Very dangerous, especially on a rolling and pitching deck with waves crashing over the stern.

This is a towing winch with a heavy-duty air-cooled brake.

I can’t remember the official term for this one. It is built into the deck very near to the stern of the rug or AHT. The two halves can be retracted fully into the deck or rotated upwards in the shown position where they can clamp a towing or an anchor wire safely. Nobody needs to go near it, all done safely from the comfort of the bridge!

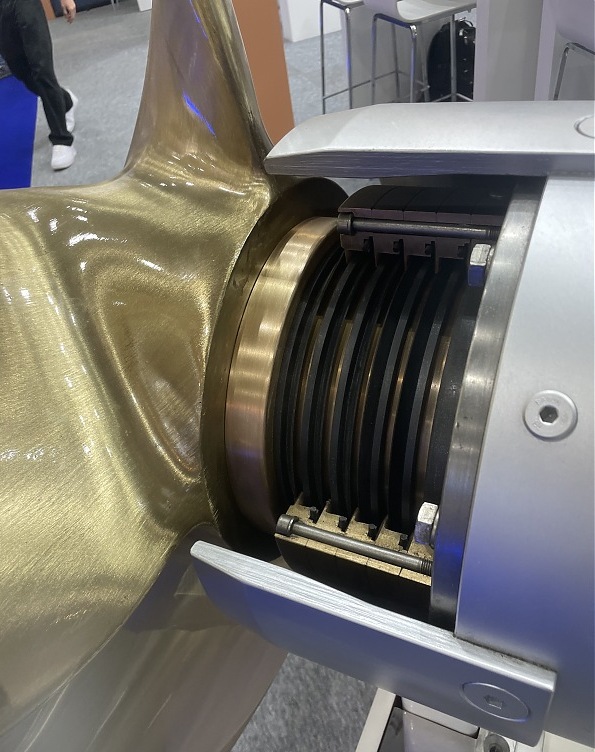

There are endless varieties and designs on how to run the prop shaft through the stern of the ship. You need bearings, lubrication and some sealing mechanism.

Whereas the shipbuilding industry in the Netherlands has moved abroad for a large part, we still have a lot of ship maintenance yards and specialised workshops. Anything from fixing a deck crane, a winch, or a hull repair to engine repair and maintenance.

Here you see a couple of cylinder heads from a marine diesel, that have been overhauled.

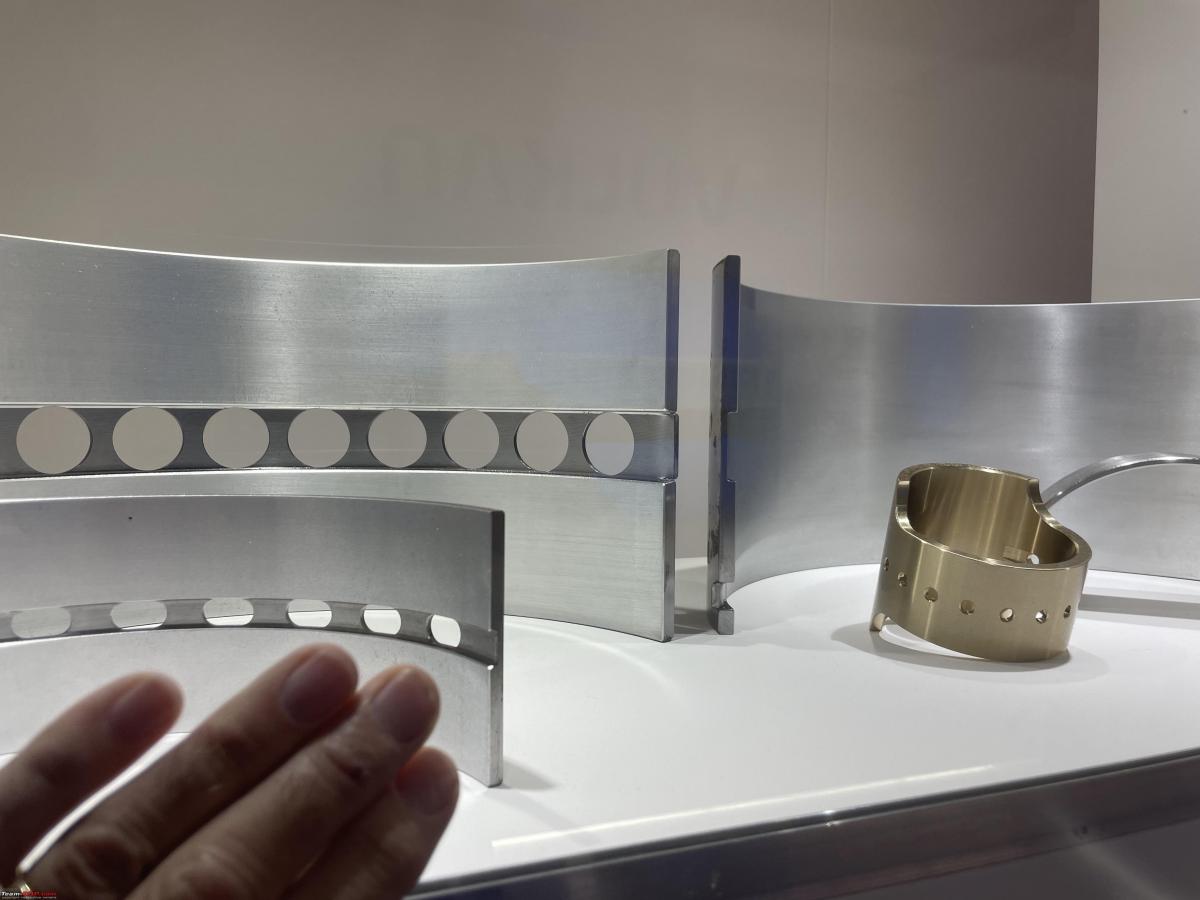

A couple of baring shells, I have held up my hand to get some idea of size. Compare this to your humble car engine. Even the bearings on my mighty Jaguar 4.0L V8 are tiny compared to these.

And then there are still a far cry removed from the really large bearings on slow 2 stroke engines!

Continue reading Jeroen’s experience at the exhibition for BHPian comments, insights and more information.

Source: Read Full Article